Our uncompromising commitment to quality management

Our company’s mission is to be a trusted, reliable, and sought-after organization, driven by a commitment to fully meeting customer needs and expectations at every stage of our operations. To achieve this goal, we are dedicated to the following principles:

Prioritizing safety and health

We place the health and safety of patients, practitioners, users, and third parties at the forefront of our operations.

01

Manufacturing excellence

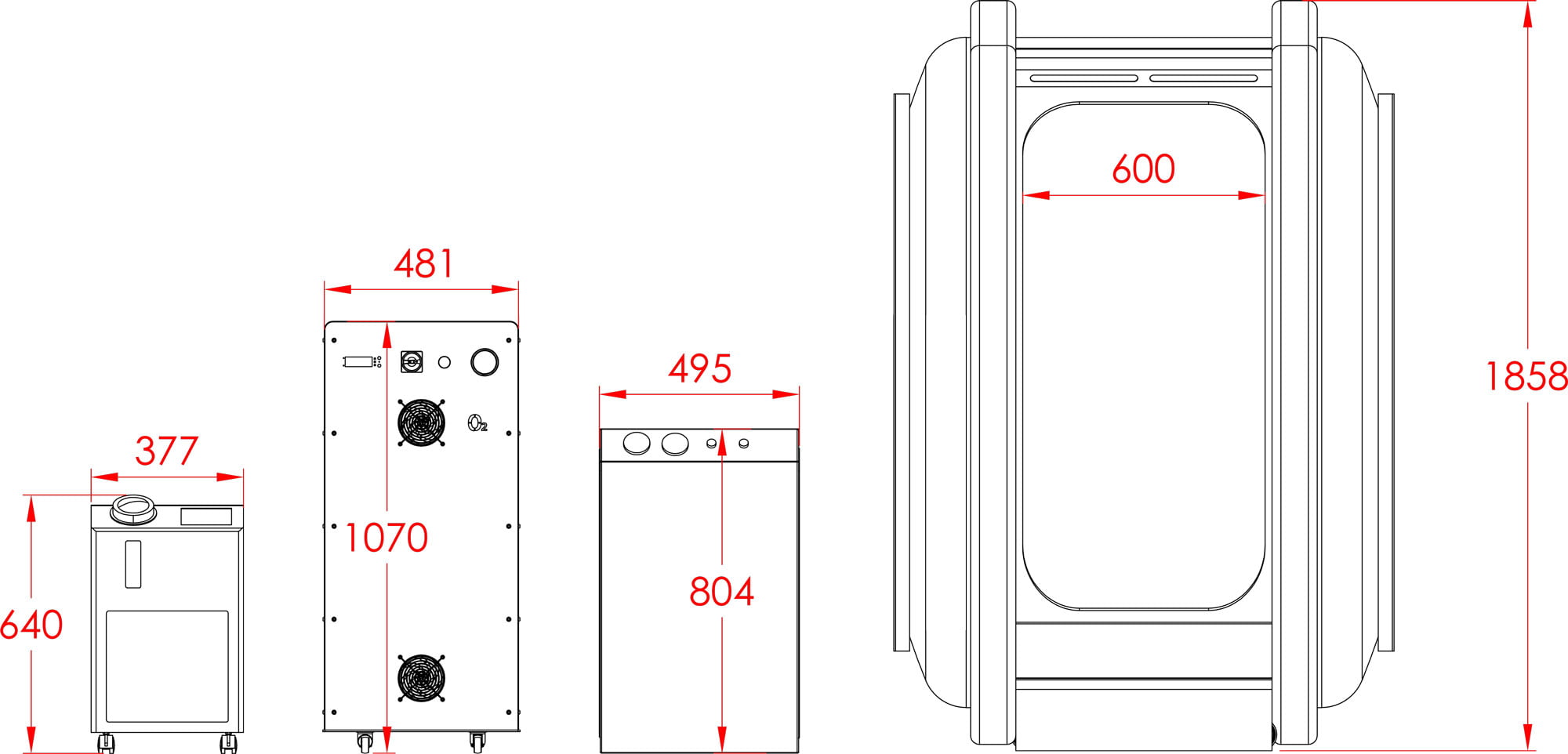

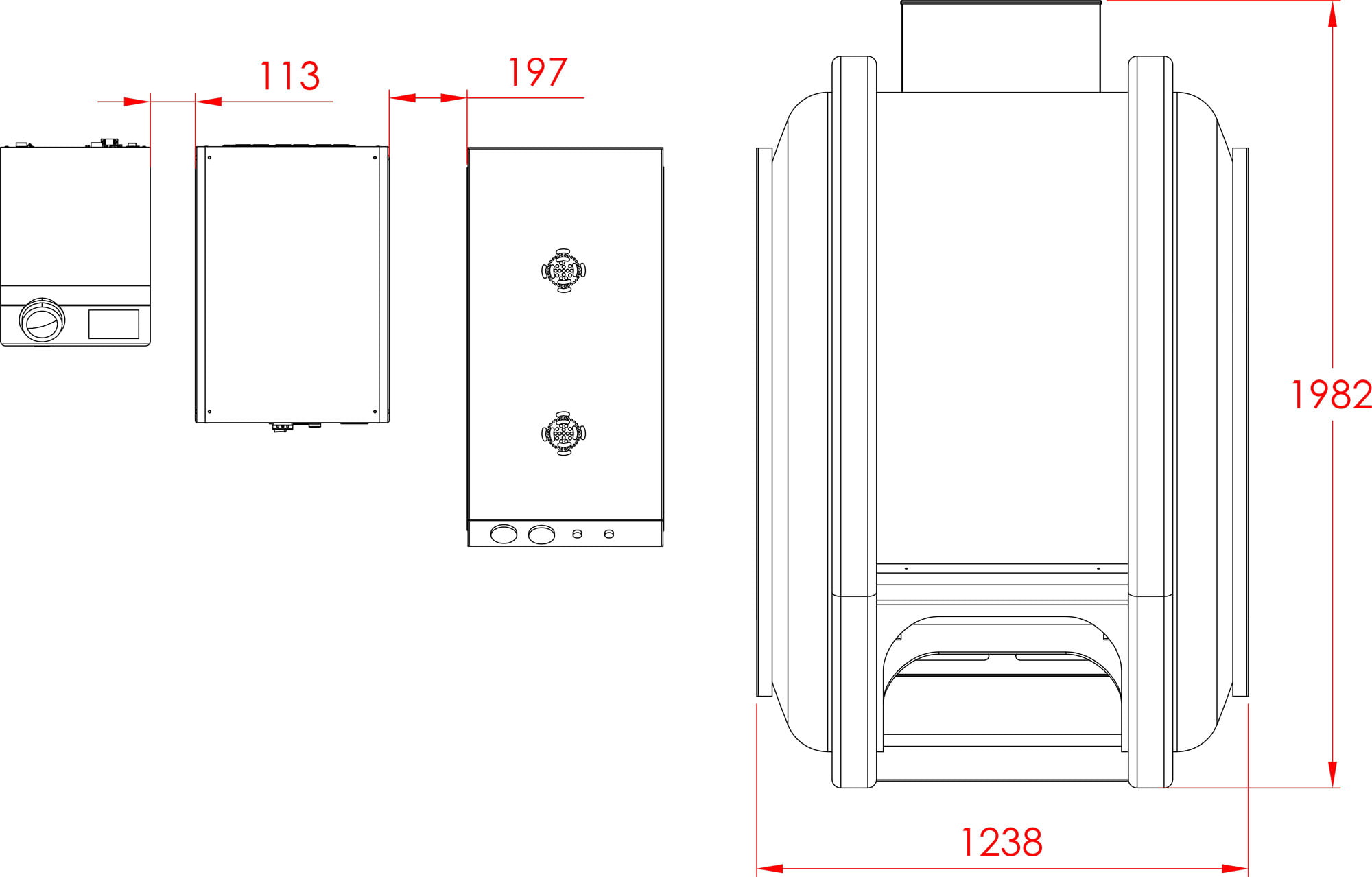

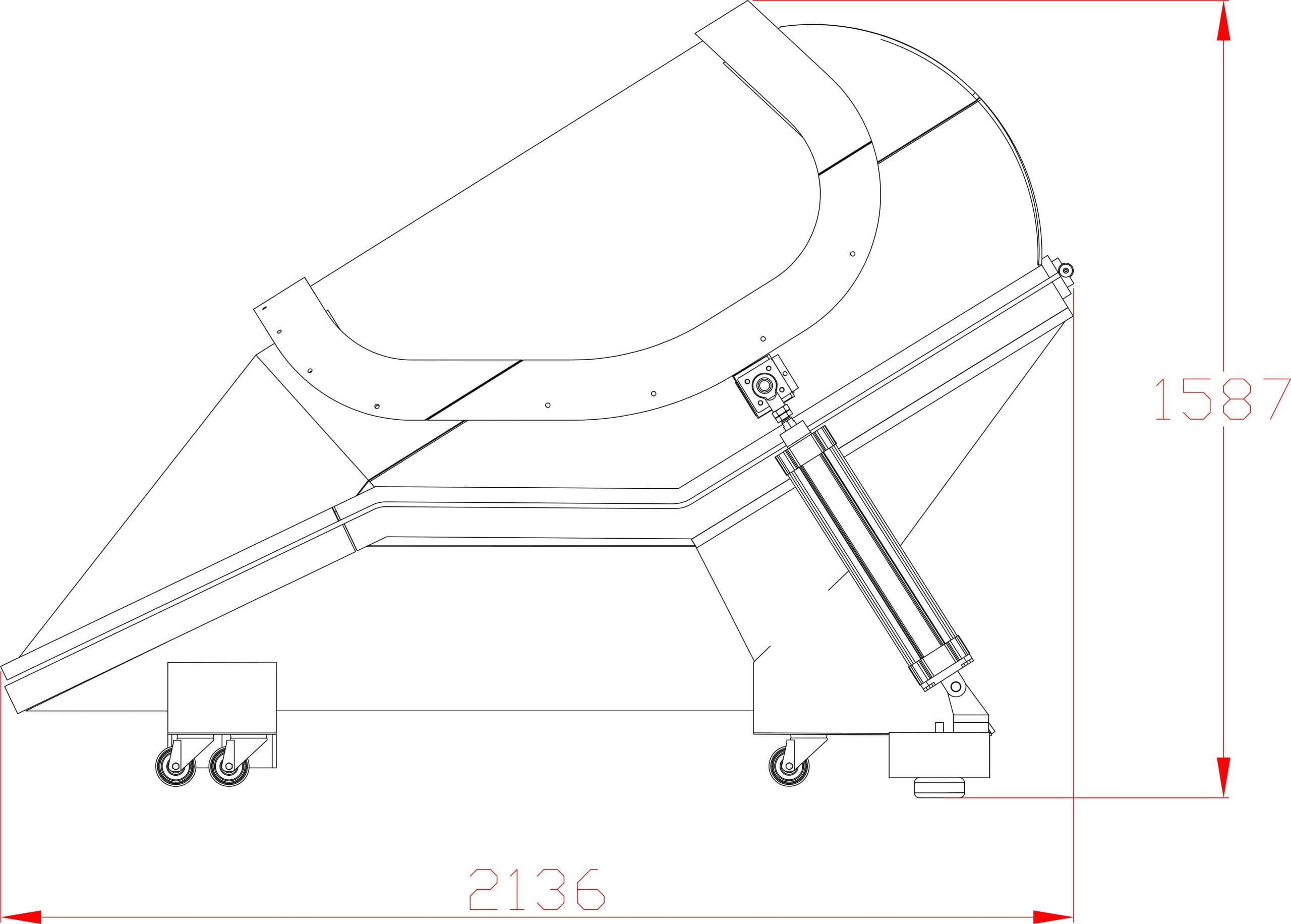

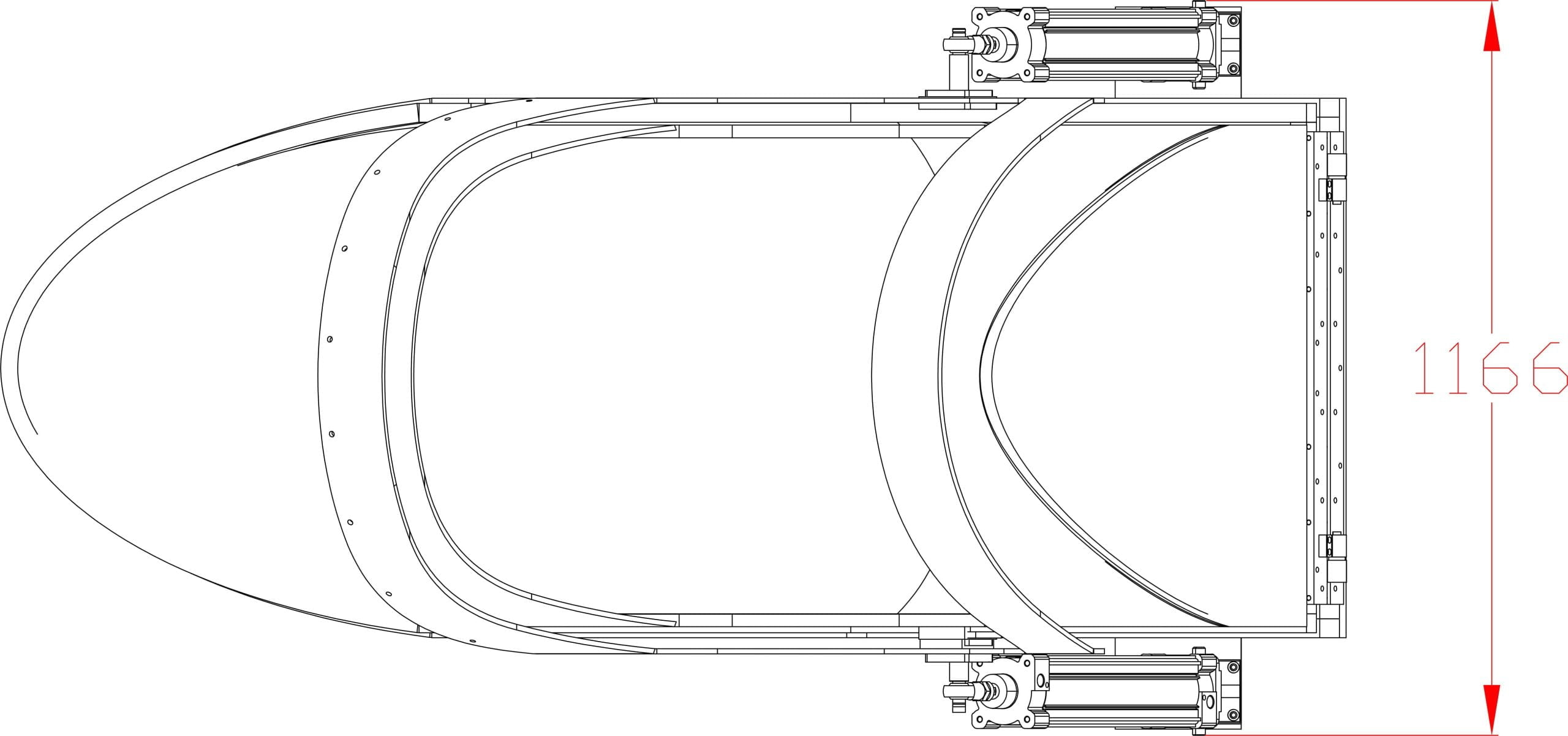

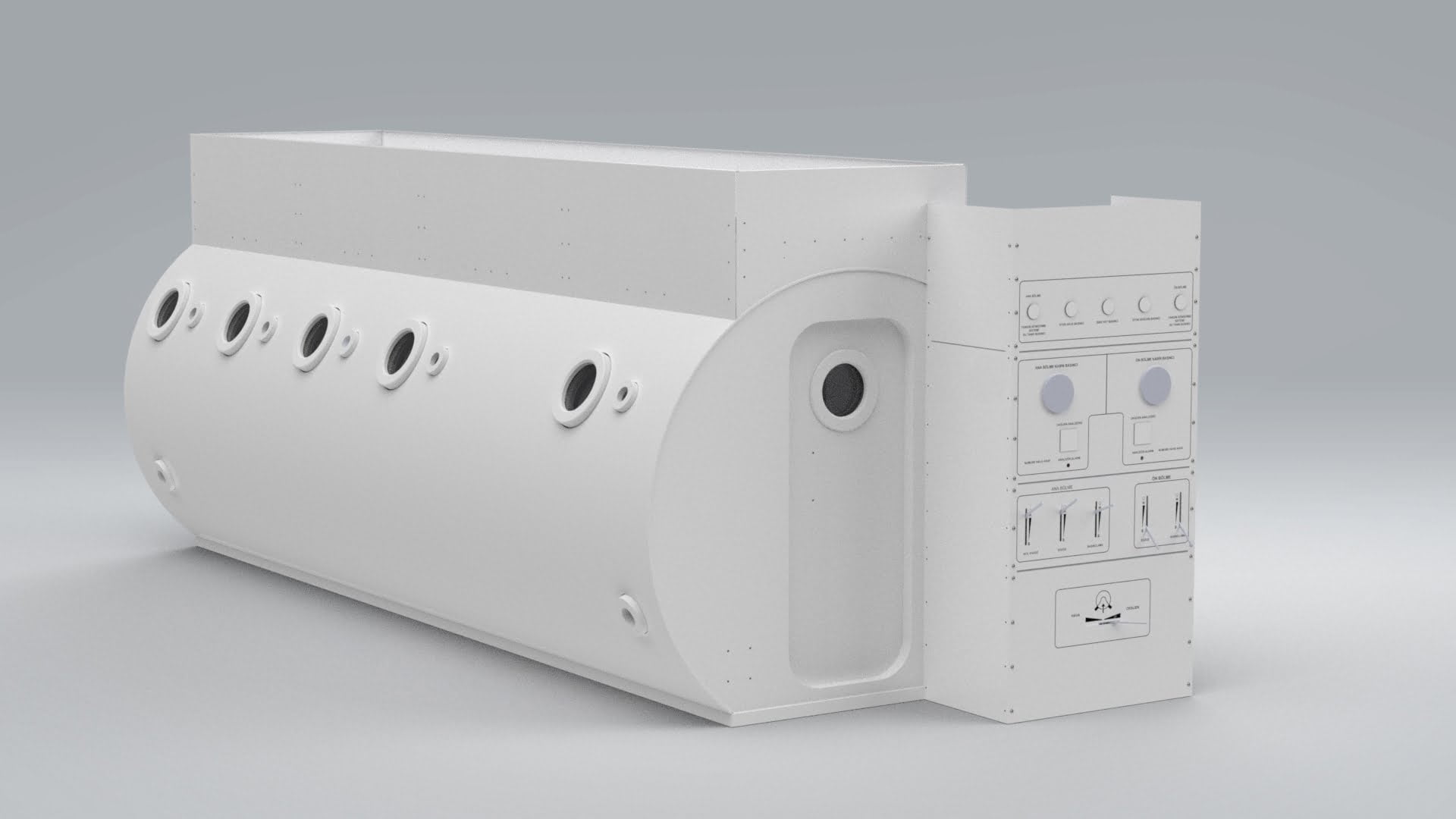

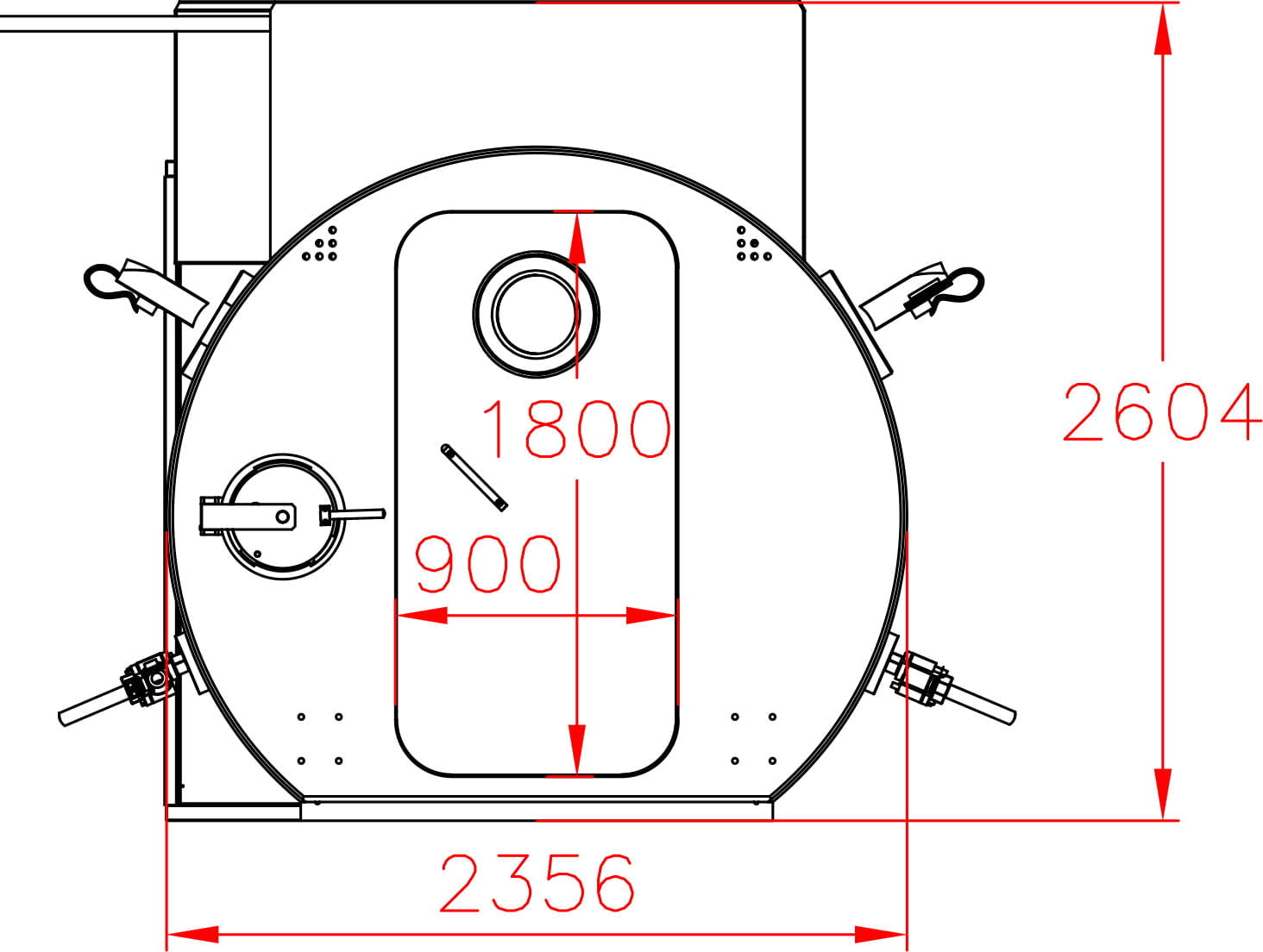

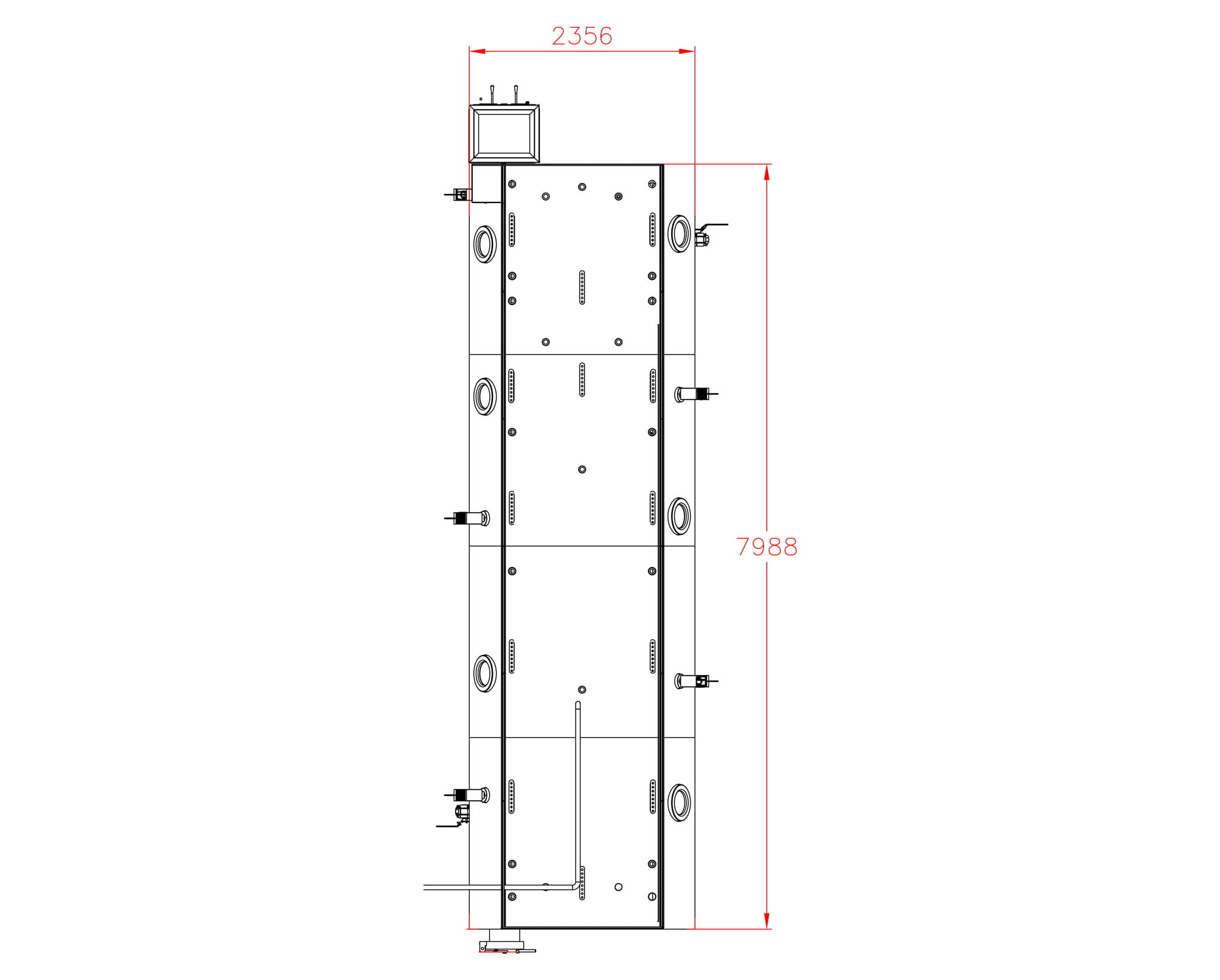

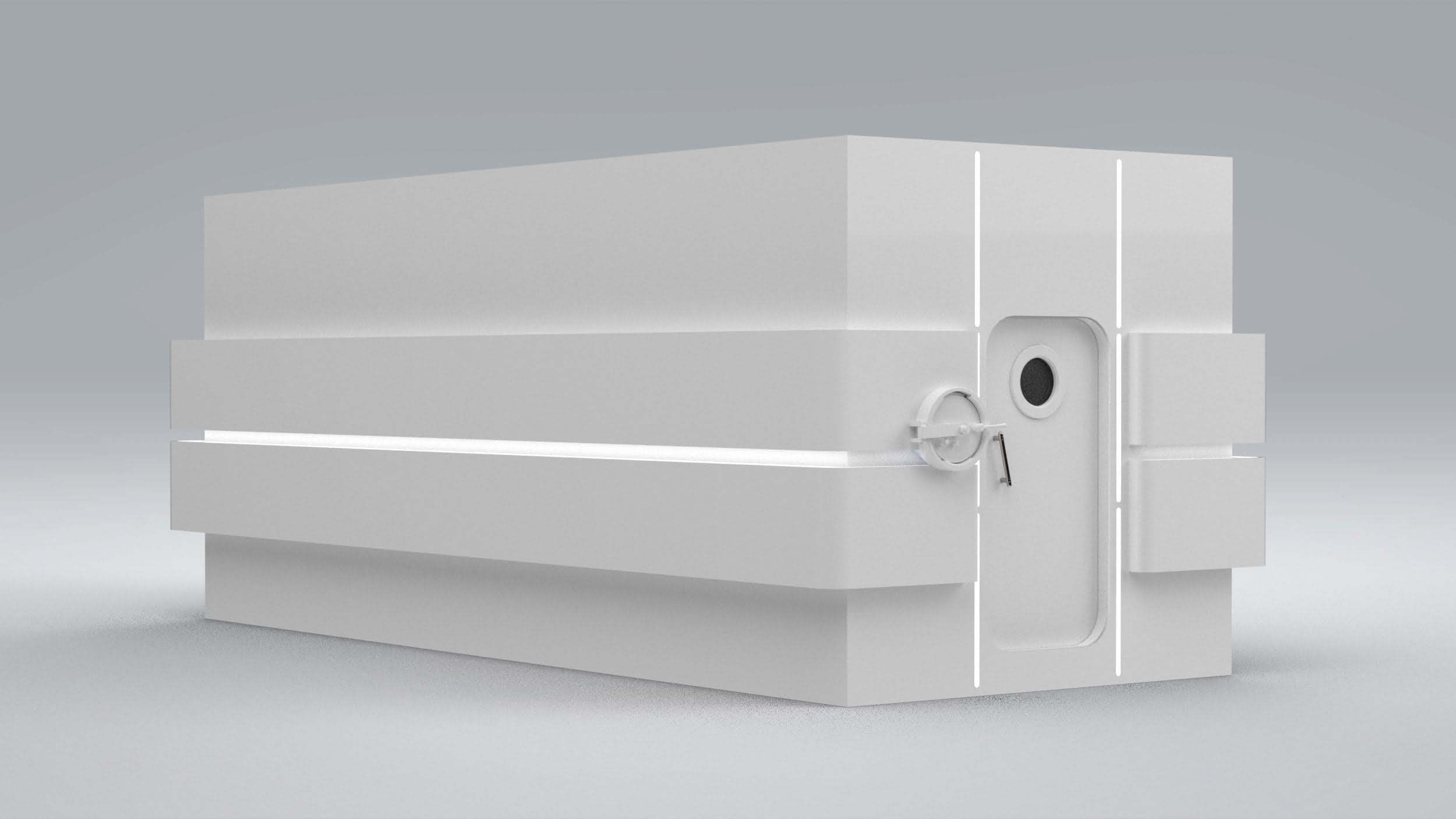

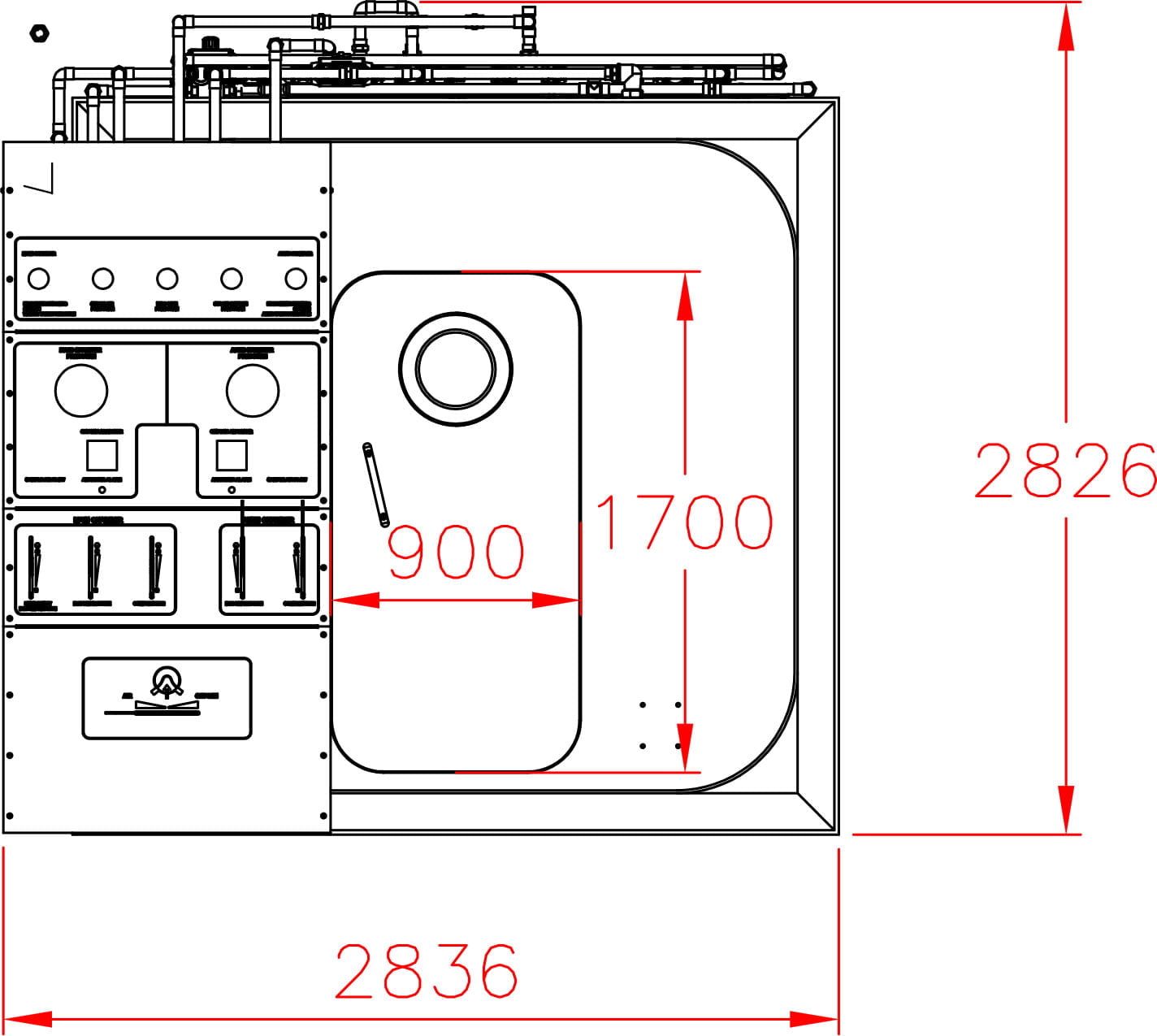

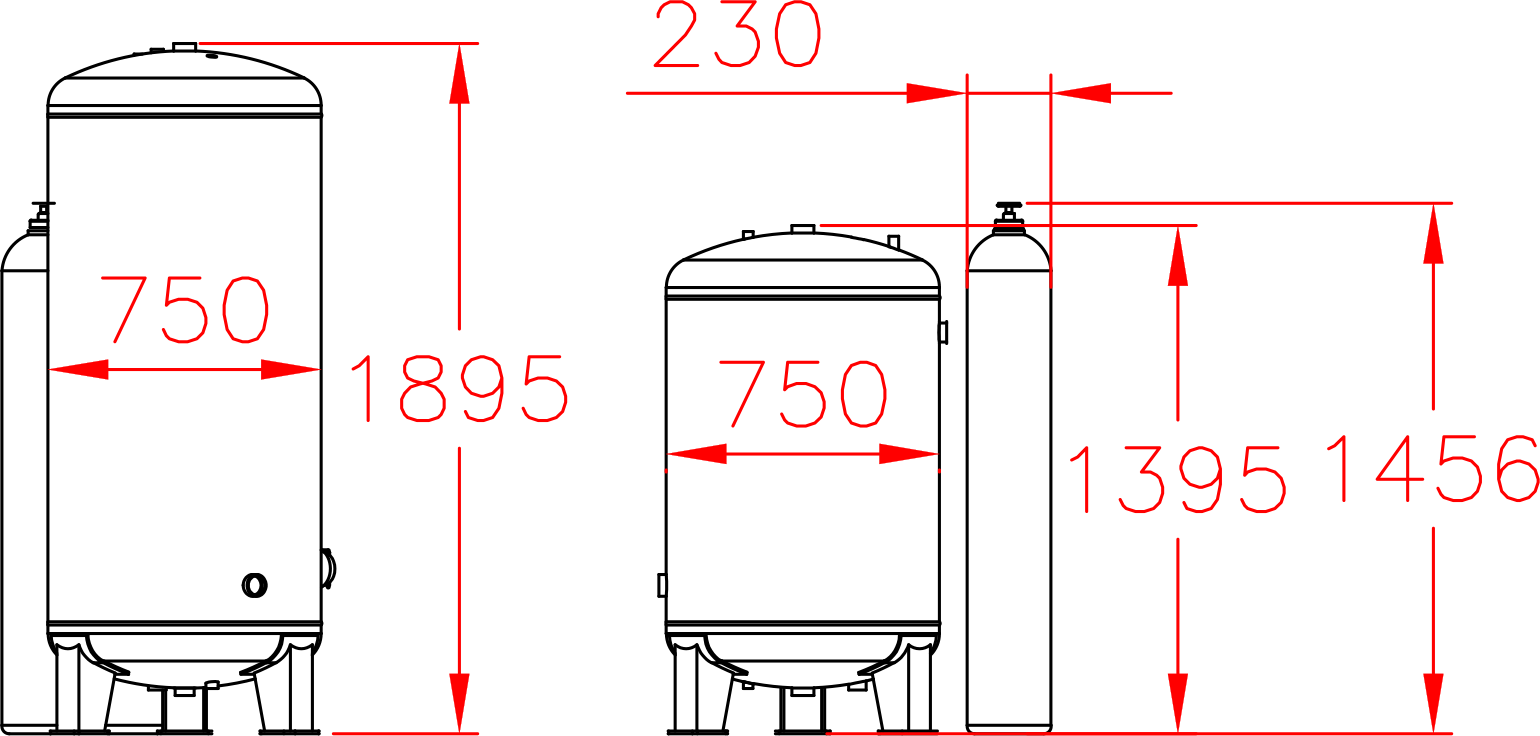

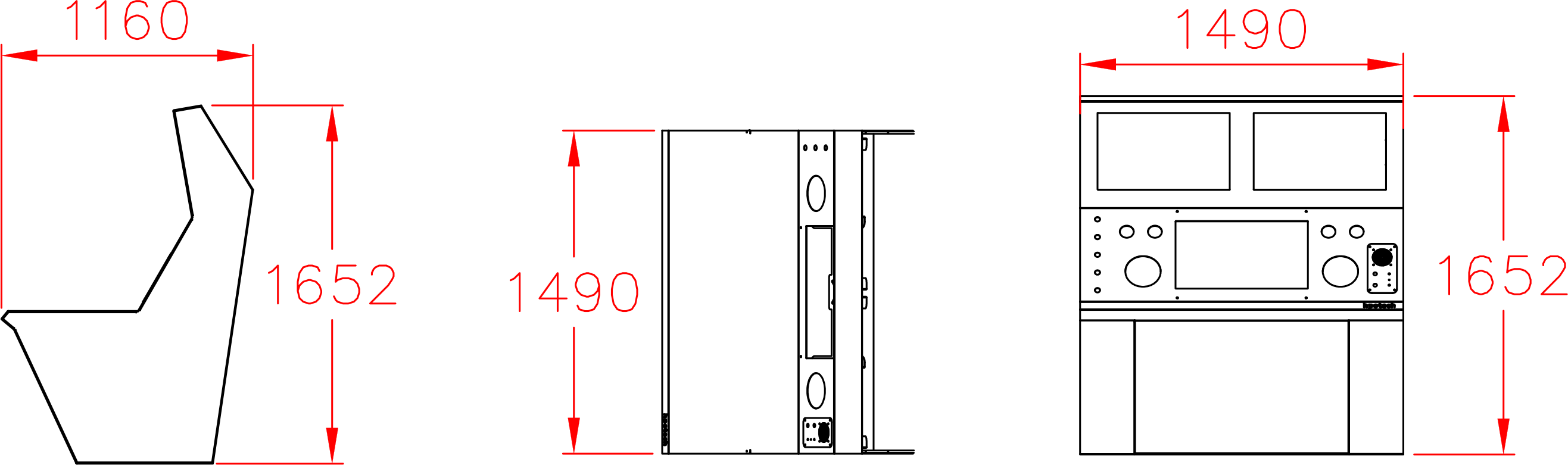

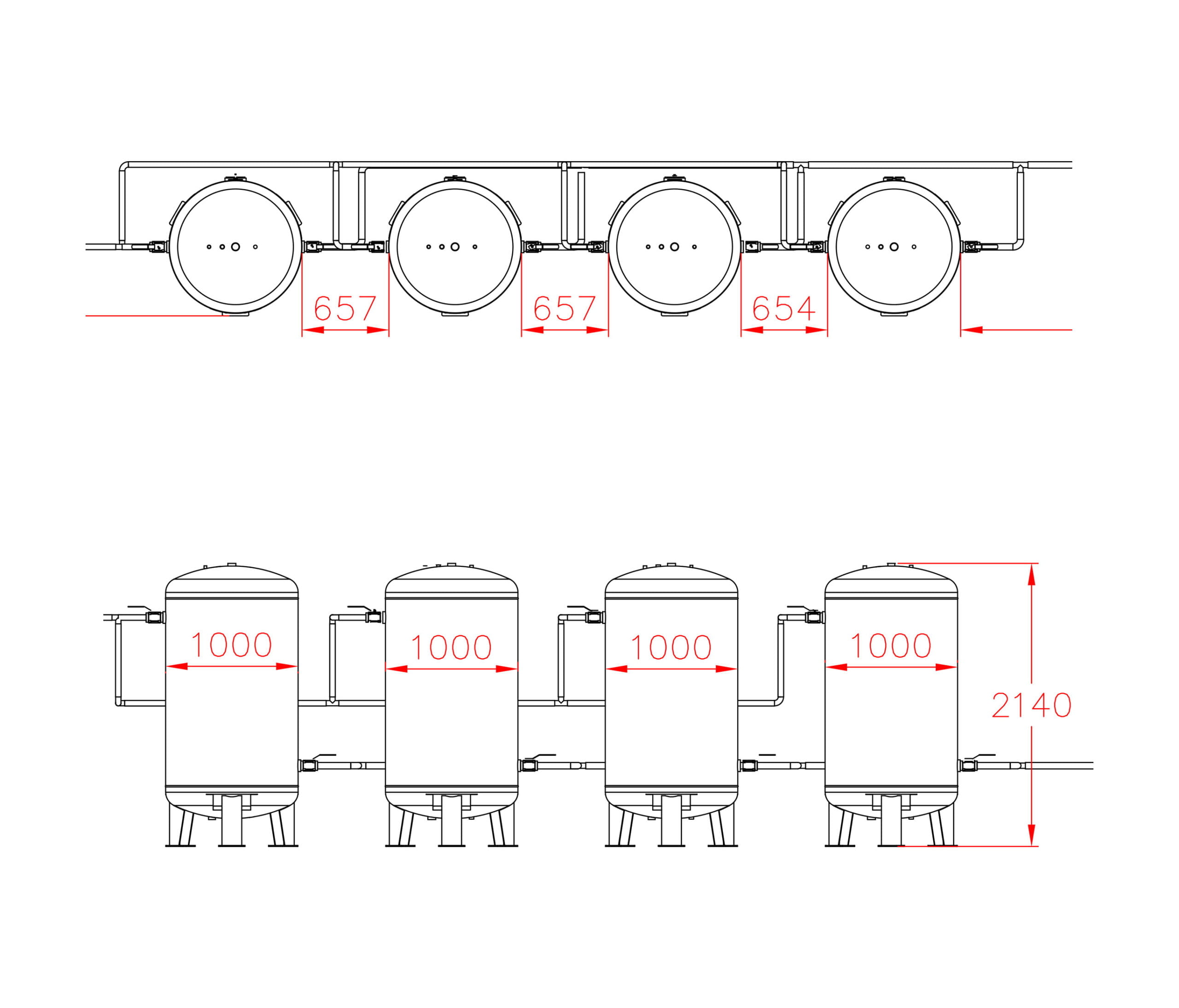

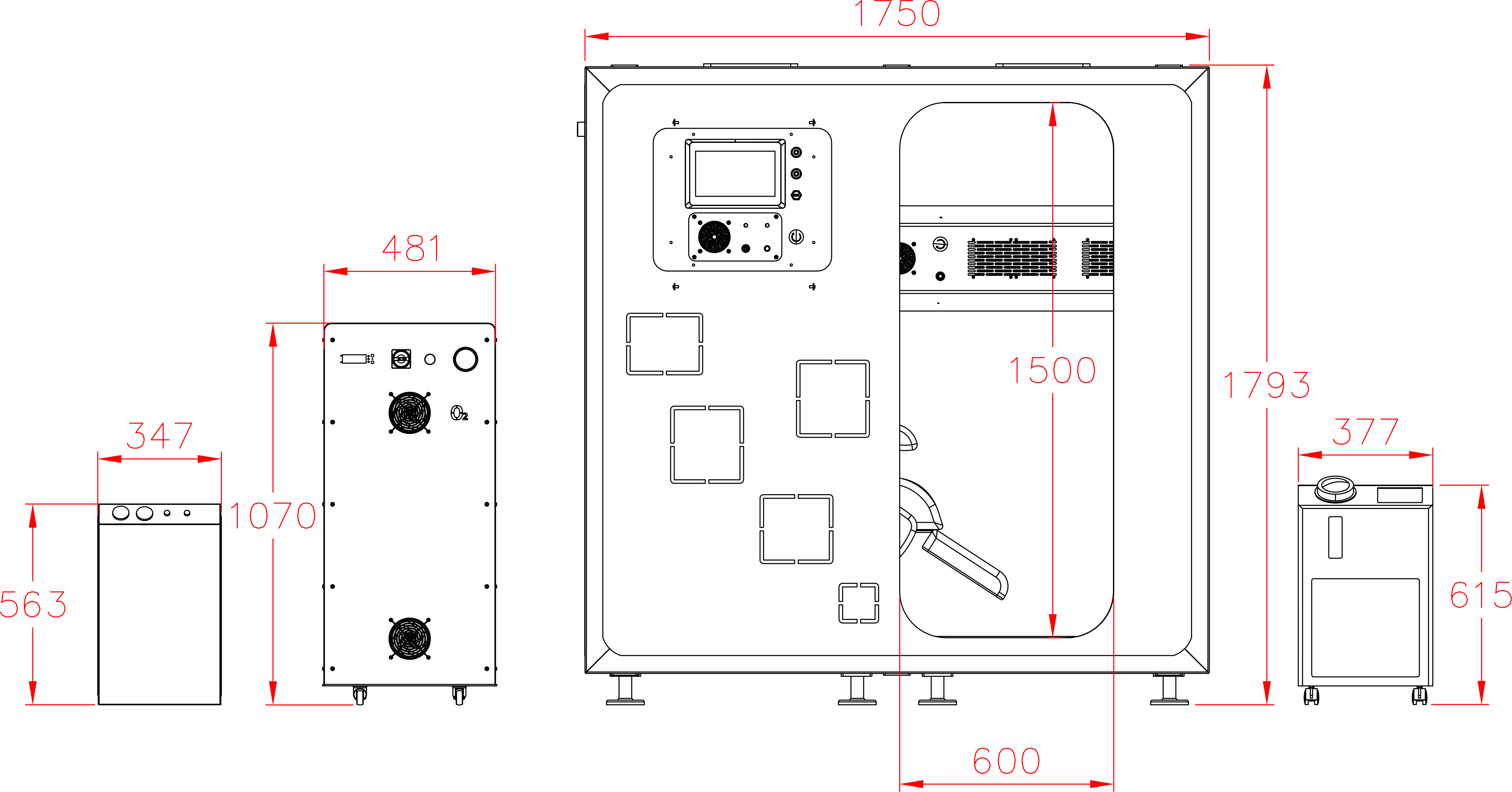

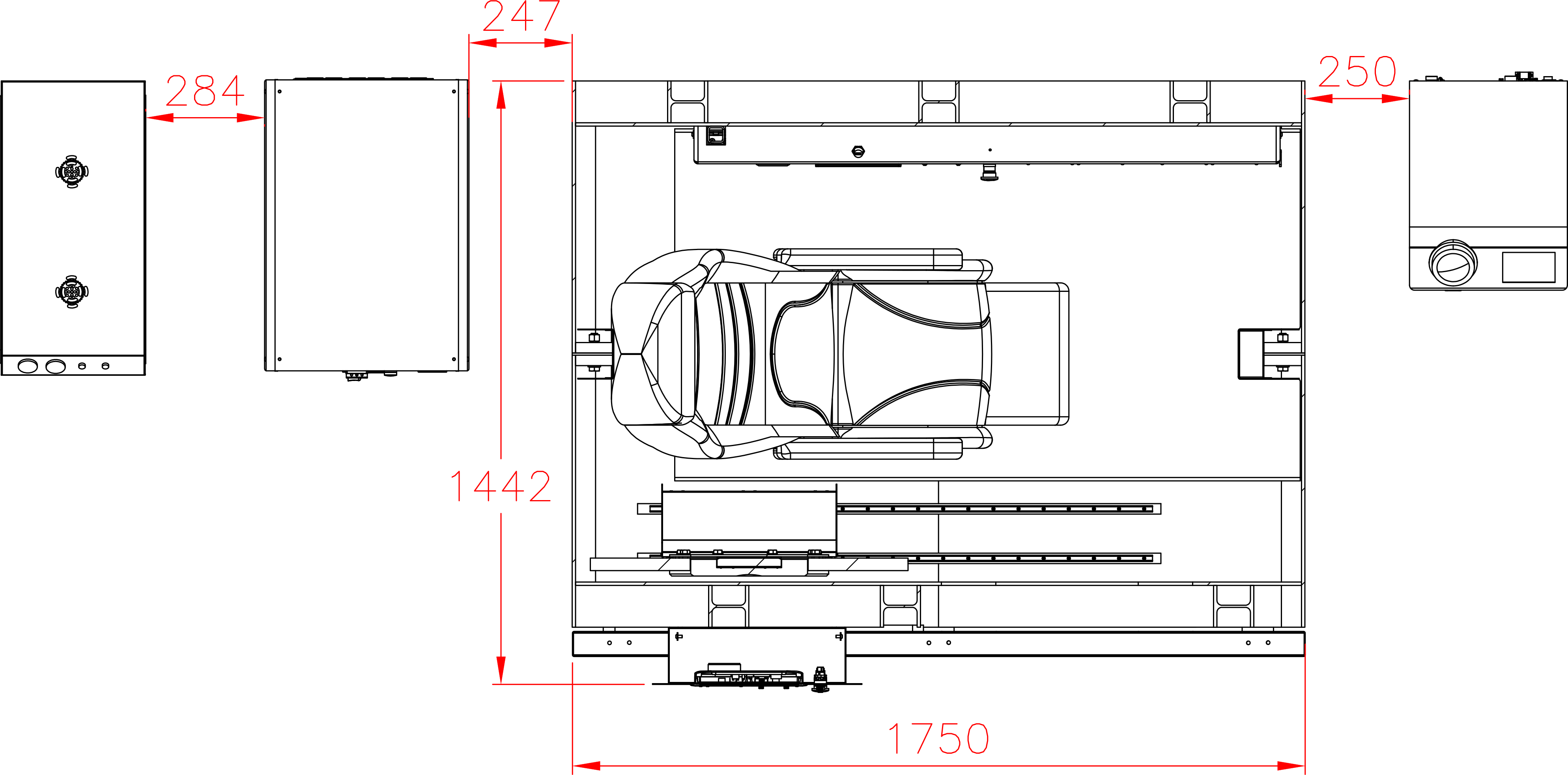

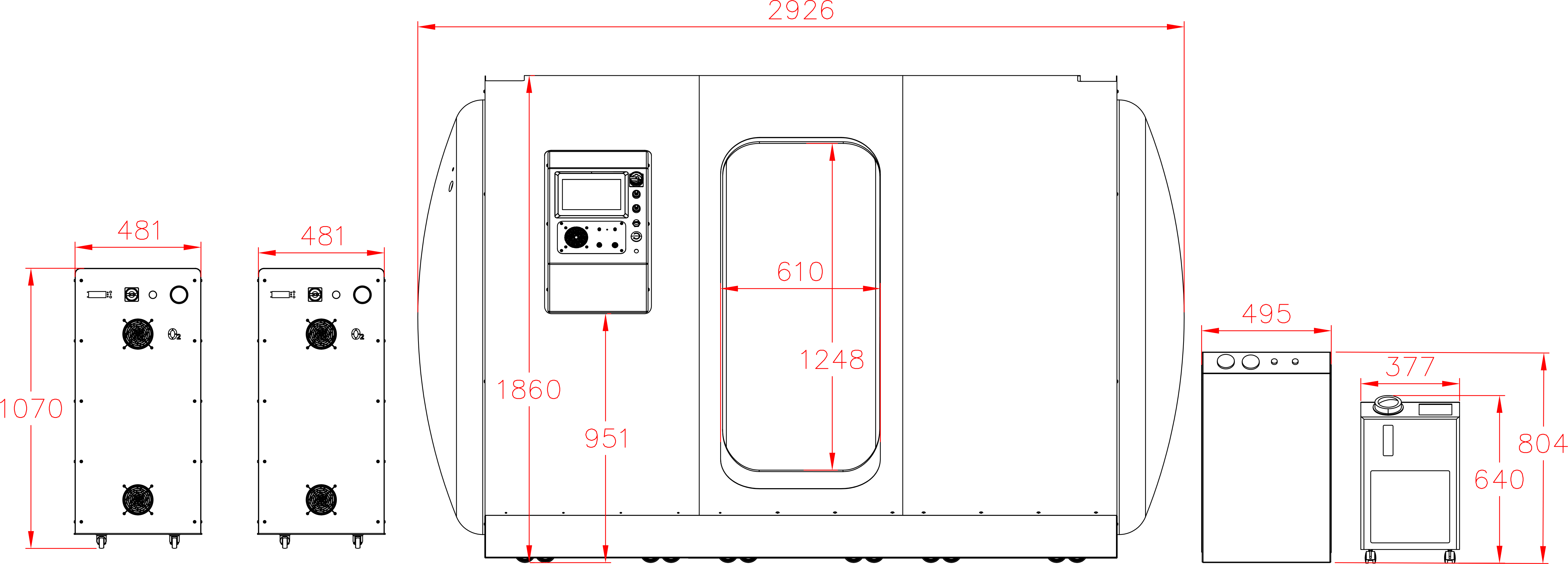

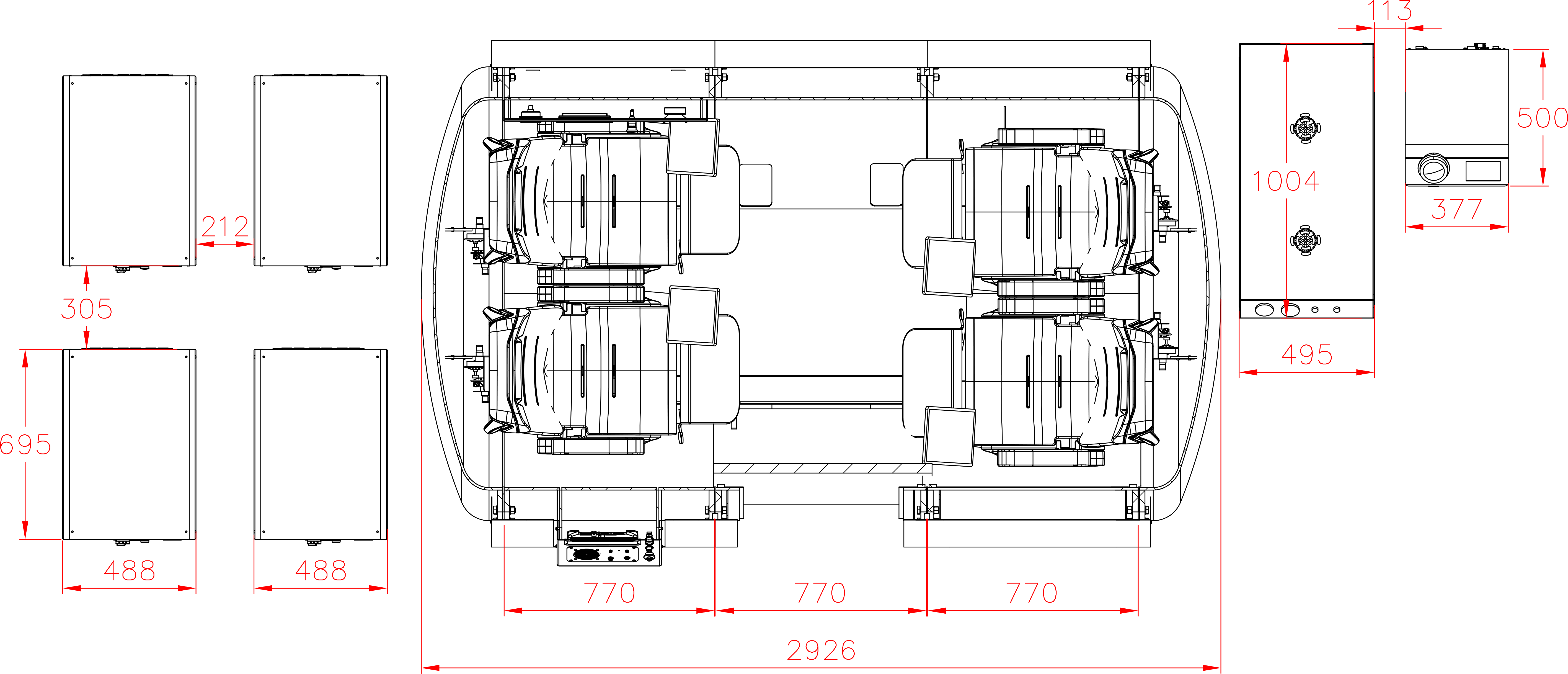

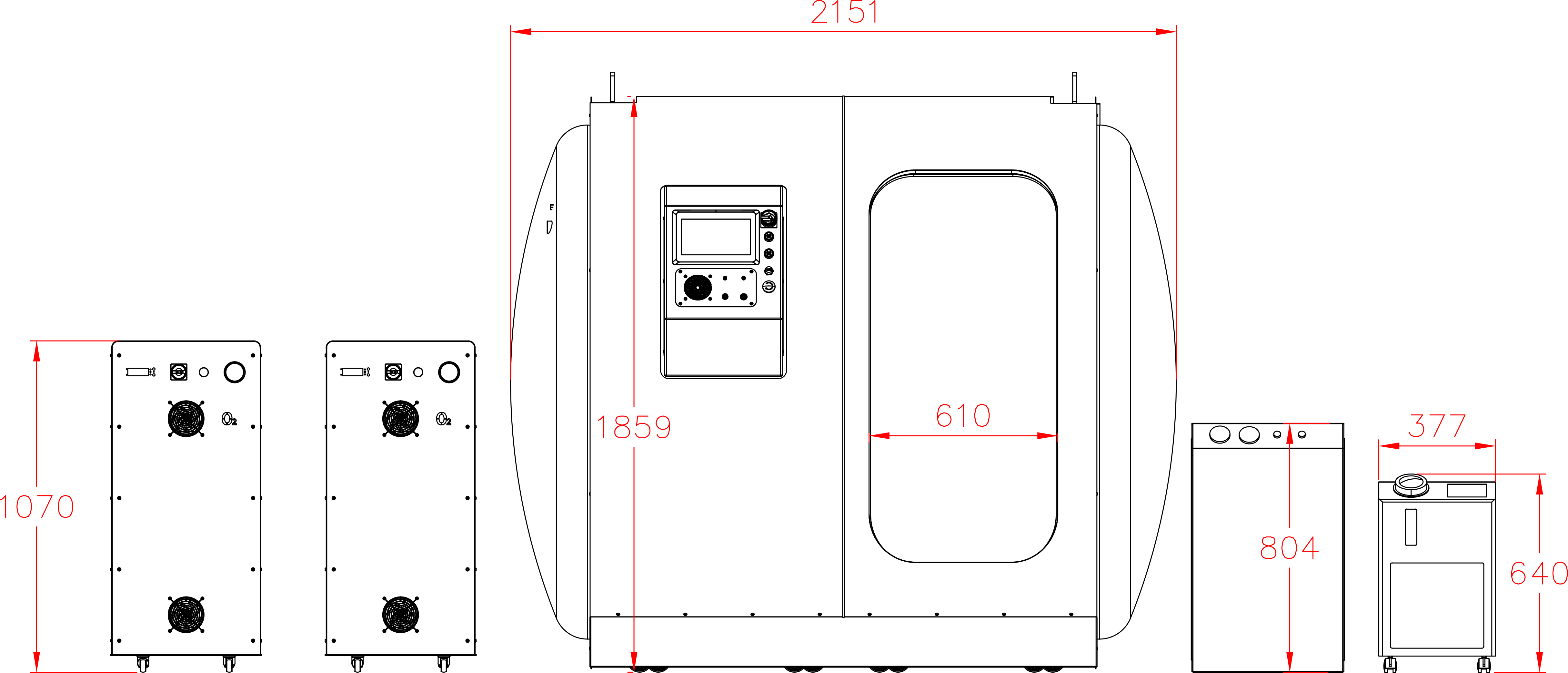

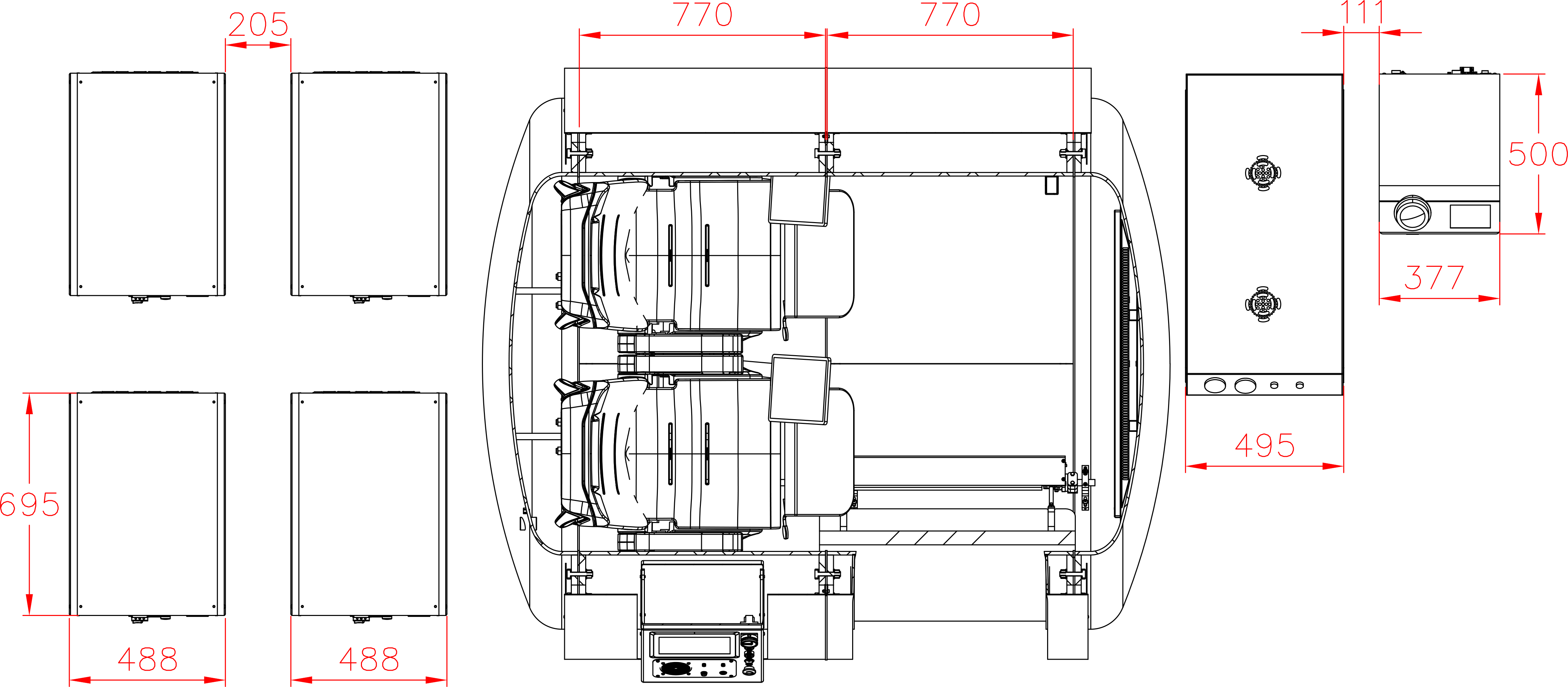

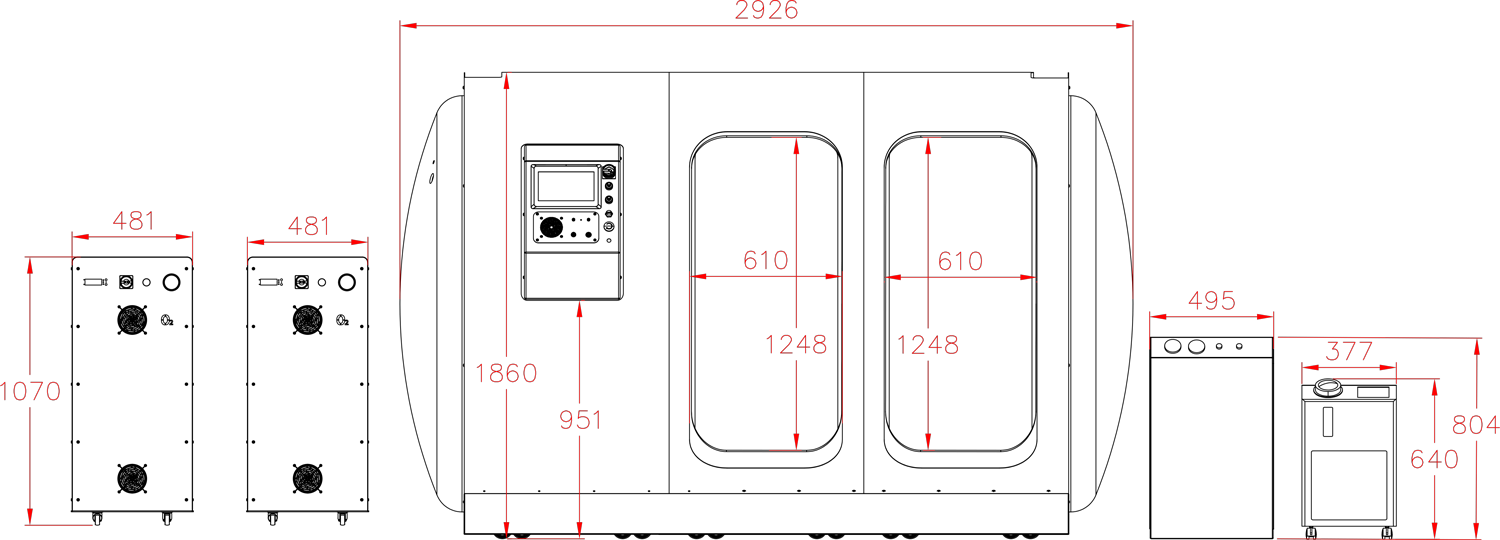

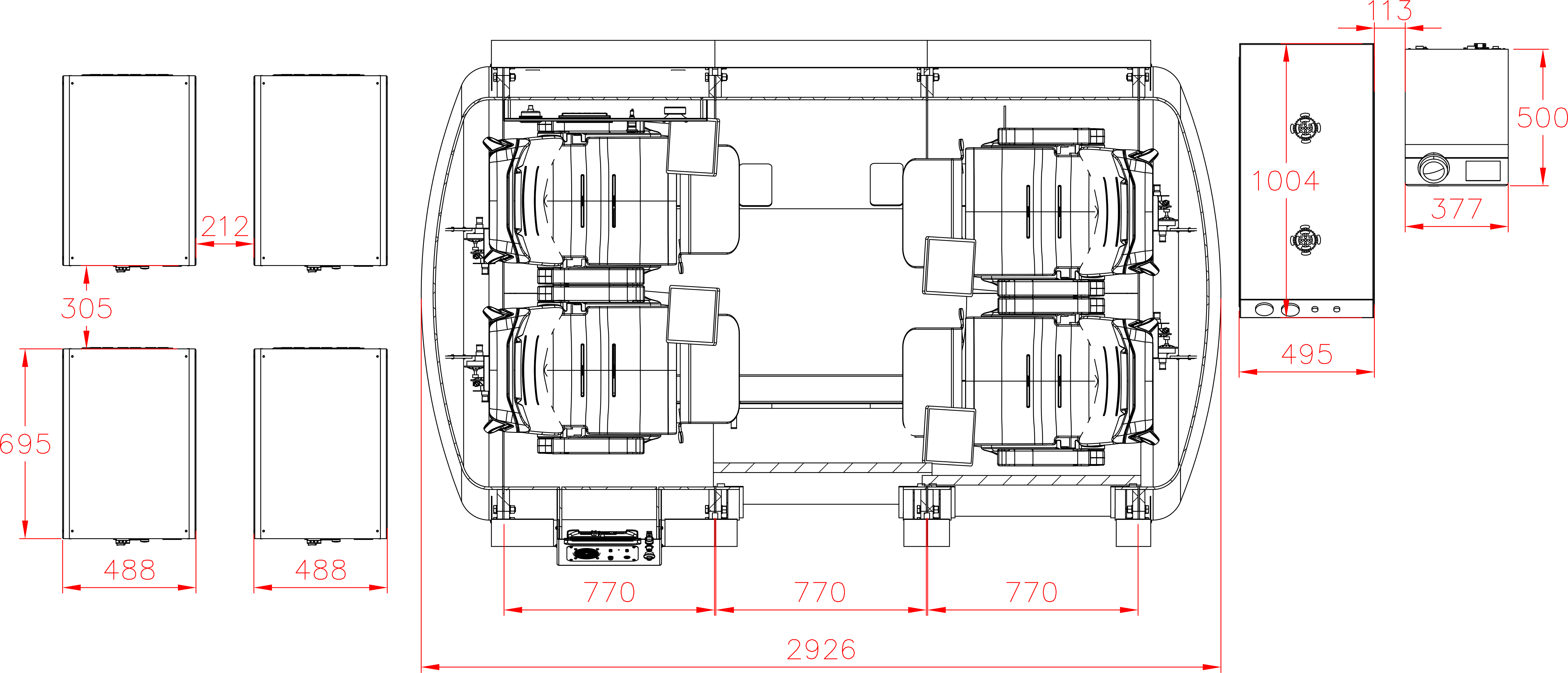

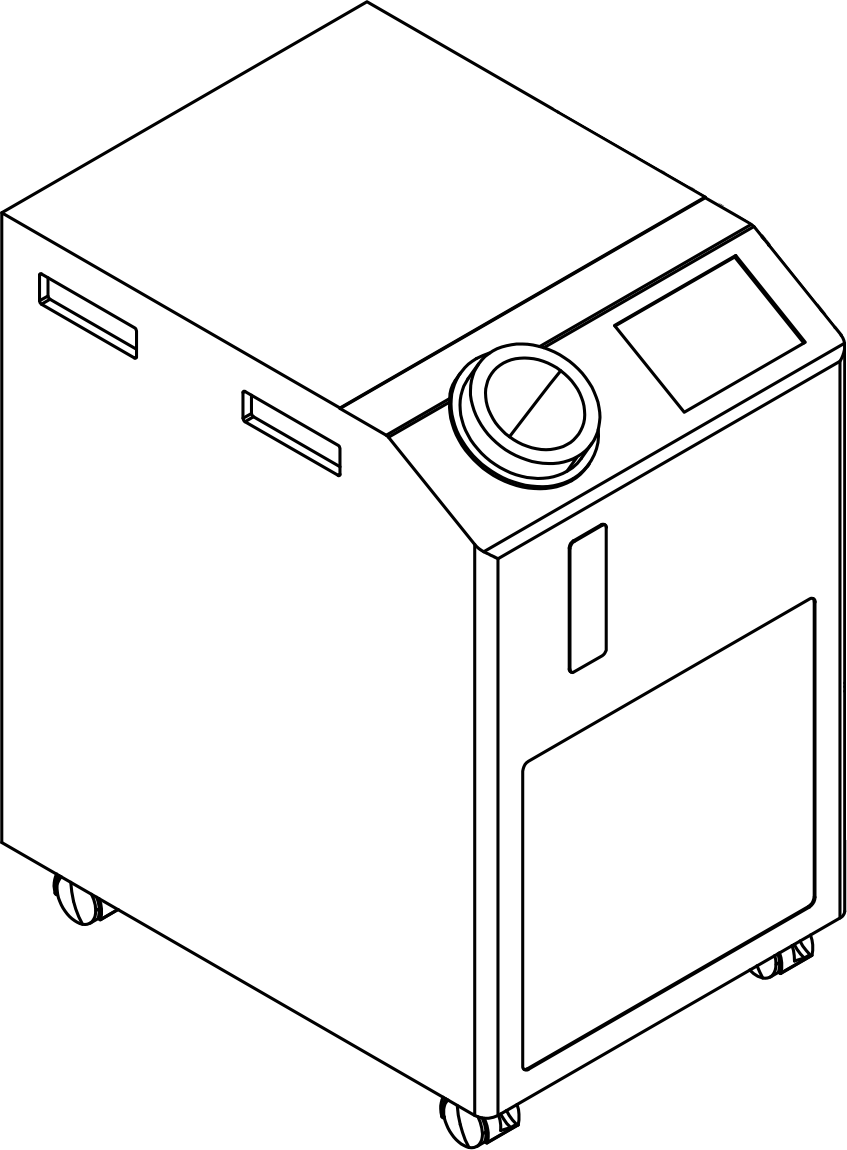

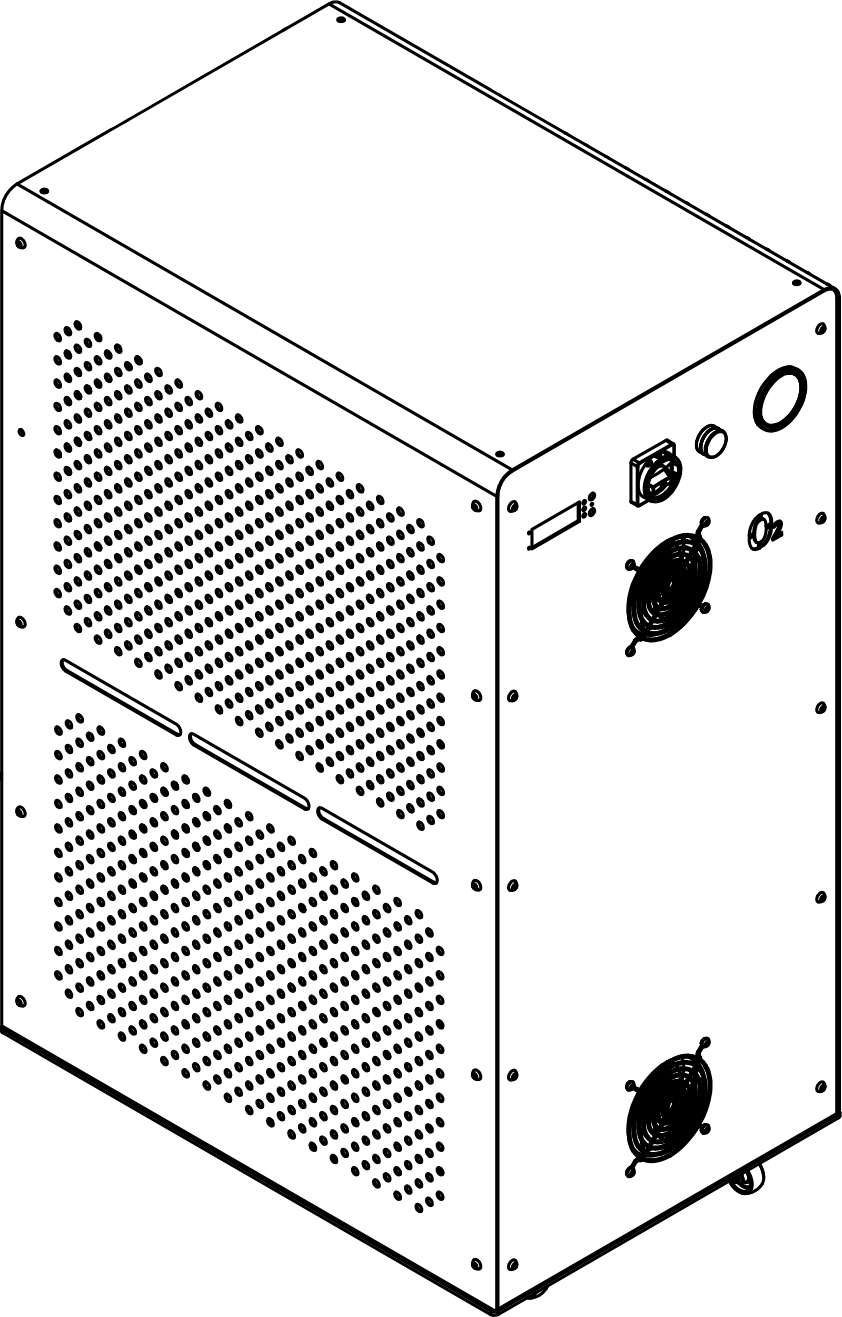

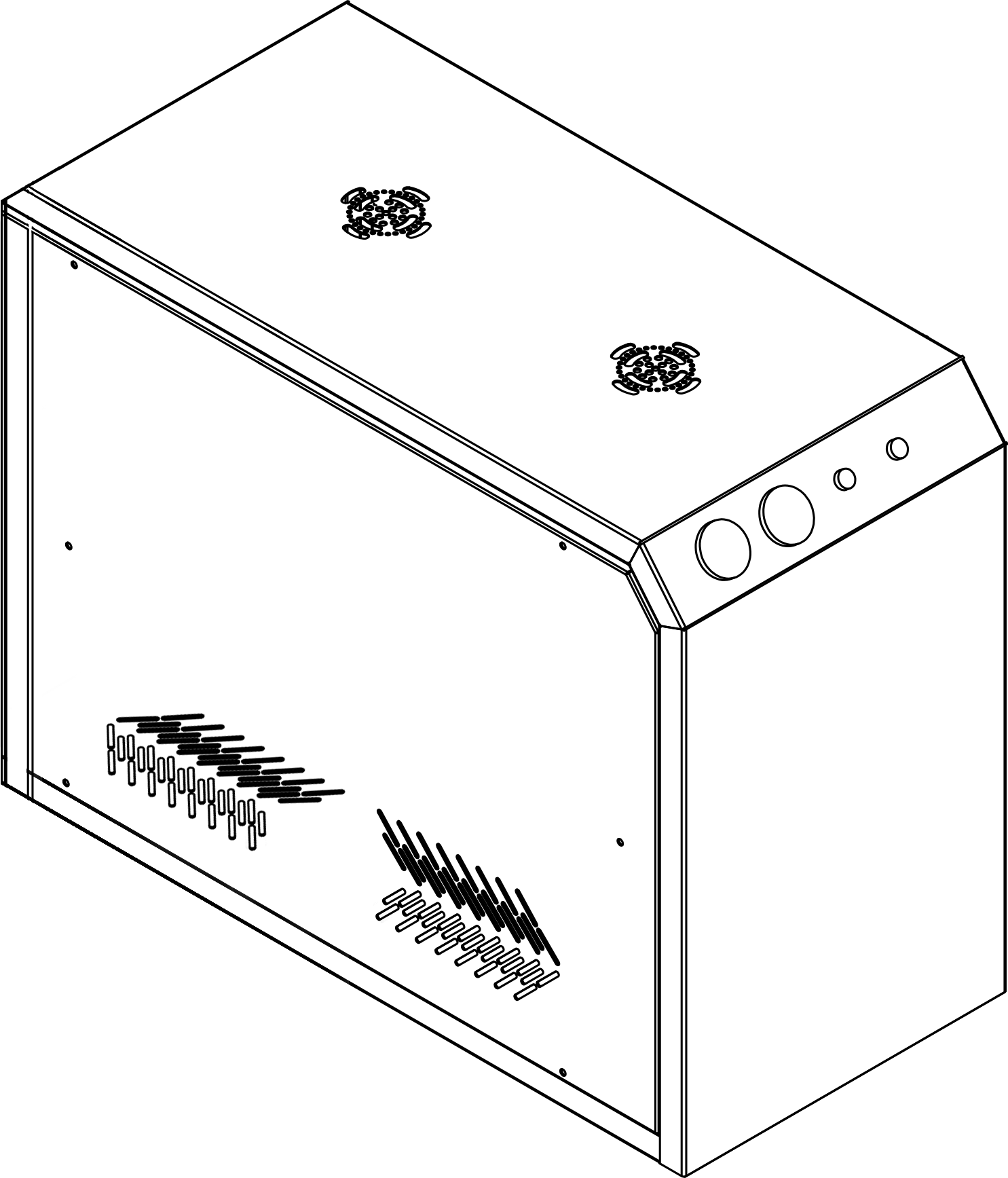

We produce high-quality medical devices, such as Hyperbaric Chamber Systems, designed for oxygen therapy applications involving pressure differentials on the human body. These products meet national and international standards as well as all legal requirements.

02

Commitment to customer satisfaction

Customer satisfaction is at the core of our business principles.

03

Effective Quality Management systems

We ensure the ongoing effectiveness of our quality management system by adhering to national and regional legislative requirements.

04

Employee development and engagement

We prioritize the continuous training of our employees, supporting their active participation in our quality management system.

05

Risk-Focused Quality Assurance

We apply a risk-based approach to developing and implementing our quality management system. This includes:

- Fully meeting customer, legal, and regulatory requirements.

- Maintaining and improving the system’s effectiveness.

- Ensuring all employees understand and uphold quality standards.

06

Setting and reviewing quality objectives

We establish measurable quality objectives and regularly review them to ensure alignment with our mission and continuous improvement.

07

Certifications and Total Quality Management for hyperbaric chamber manufacturing

Our Total Quality Management system includes all aspects across design, manufacturing, testing, functionality, and customer service to ensure our hyperbaric oxygen systems are effective in therapy, but also safe, reliable, and accessible for patients.

Certifications

Holding all the important ASME-PVHO, PED, CE, ISO, NFPA, etc certifications, our products are manufactured, tested, and certified to the highest quality and safety standards. We comply with all international safety and quality regulations.

Safety and compliance

Safety standards and certifications play a vital role in guaranteeing the quality and reliability of hyperbaric chambers used for hyperbaric oxygen therapy (HBOT).

Quality testing

Our quality control team coordinates the manufacturing and third-party testing process according to international regulations, procedures, and criteria for the certification of medical devices for medical HBOT & wellness applications.

Quality control

Each hyperbaric chamber is inspected by Türk Loydu after manufacturing in compliance with the management systems standards in quality, environmental safety, occupational health and safety, energy management, and structural integrity.

Hydrostatic Testing for Hyperbaric Chambers

Hydrostatic testing plays a critical role in guaranteeing the safety and structural integrity of hyperbaric chambers. This non-destructive quality control procedure involves pressurizing the chamber with water (deionized water to avoid corrosion) to a level exceeding its maximum operating pressure.

By simulating the real-world pressure conditions of HBOT sessions, hydrostatic testing helps identify any weaknesses in the chamber’s materials, welds, or seals before they pose a risk during therapy. This important quality control step ensures patients can experience the benefits of HBOT with confidence, knowing the chamber has undergone rigorous testing for leaks and structural integrity.